Production Capacity

A) Mold design and manufacture

I. The company owns two mold design and manufacturing centers of Suzhou Insut and Zhangzhou Insut, and has the design and processing capabilities of precision injection mold, dual-color injection mold, embedded injection mold, gas-assisted mold, IMR mold and other molds, and can manufacture 90 sets of molds per month.

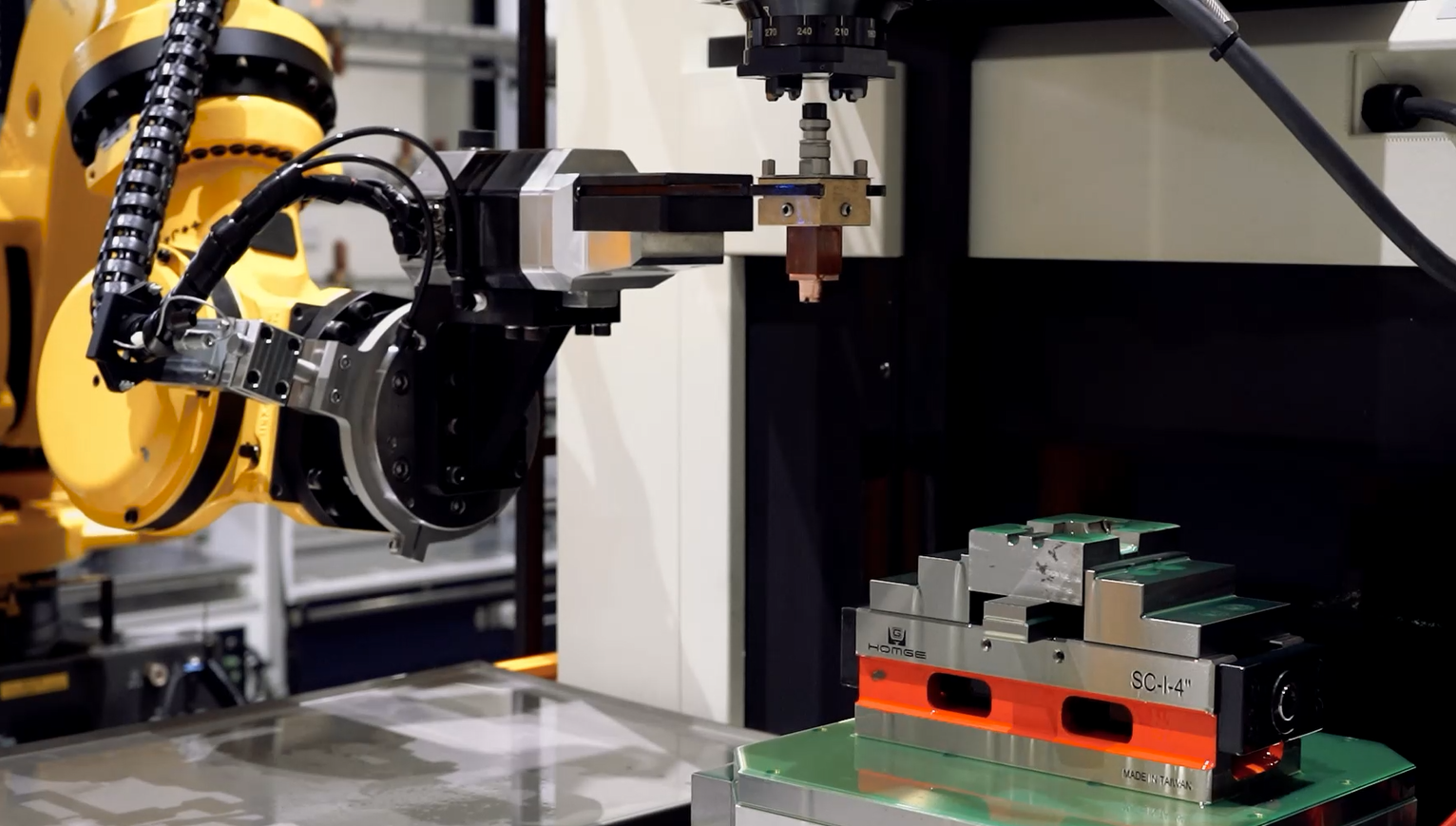

Ii. The mold manufacturing center has a series of domestic and foreign advanced mold processing and measuring equipment, such as Shamir & Shadiq WEDM, Rhodes & Yongjin CNC, Makino & Ogeisso EDM, Fanaco Robot, Chase CMM. At the same time with a continuous automatic electrode machining system.

B) Injection molding ability

I. It has more than 120 precision electric injection molding machines of 6-1200T, which can meet the automatic injection molding capacity of precision structural parts, double-color injection molding, embedded injection molding, gas-assisted injection molding, miniature injection molding, IMD and so on.

Ii. In addition to common engineering plastics, materials for injection molding products include 0 degree TPE soft glue, PEEK, ABS+GF, PA+GP, POM+GF, degradable materials (PLA, wheat straw, PCR), etc.

Iii. Have standard clean injection molding workshop and ten thousand GMP workshop, which can produce consumer electronics, auto parts, medical, food, microchip and other products.

C) Surface treatment

I. There are two spraying lines for four coating and four baking rails, and five spraying lines for two coating and two baking rails. The maximum processing size is 300mm; There are two spraying lines for two coating and two baking machines, and the maximum processing size is 1.2m * 1.2m.

Ii. Equipped with a CNC gun control system and an online paint dispensing device, it has a total length of 860 meters and a maximum line speed of 14m/min.

Iii. It has 4 vacuum electroplating furnaces, which can realize vacuum electroplating of light chrome, silver, stainless steel, gold, 錆色, pearl chrome, red bronze, rose gold and other colors. The maximum processing size is mm: 1200*150

Iv. It has radium carving equipment, printing equipment, bronzing equipment, etc., which can realize radium carving, monochrome & multi-color printing, roll printing, gradient printing, large-area printing & bronzing and other processes.

D) Assembly of structural parts

I. It can realize the assembly and processing technology of product structural parts, hot melt and ultrasonic welding, CCD online monitoring, etc.

Ii. Customized development of various non-standard automation equipment, barcode traceability system and other automation and information services.

wxl@insut.com

wxl@insut.com Wanlida Industrial Park, Jinfeng Development Zone, Zhangzhou City, Fujian Province

Wanlida Industrial Park, Jinfeng Development Zone, Zhangzhou City, Fujian Province