Zhangzhou Insut Industry Co., Ltd.

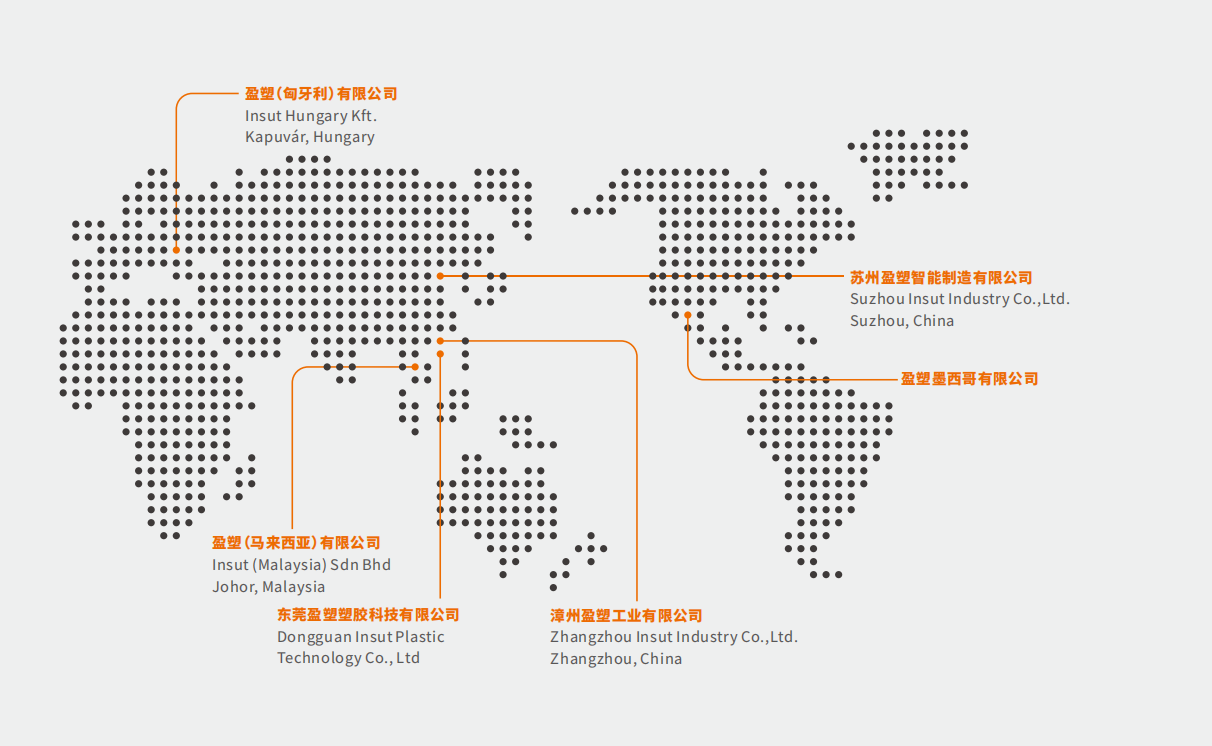

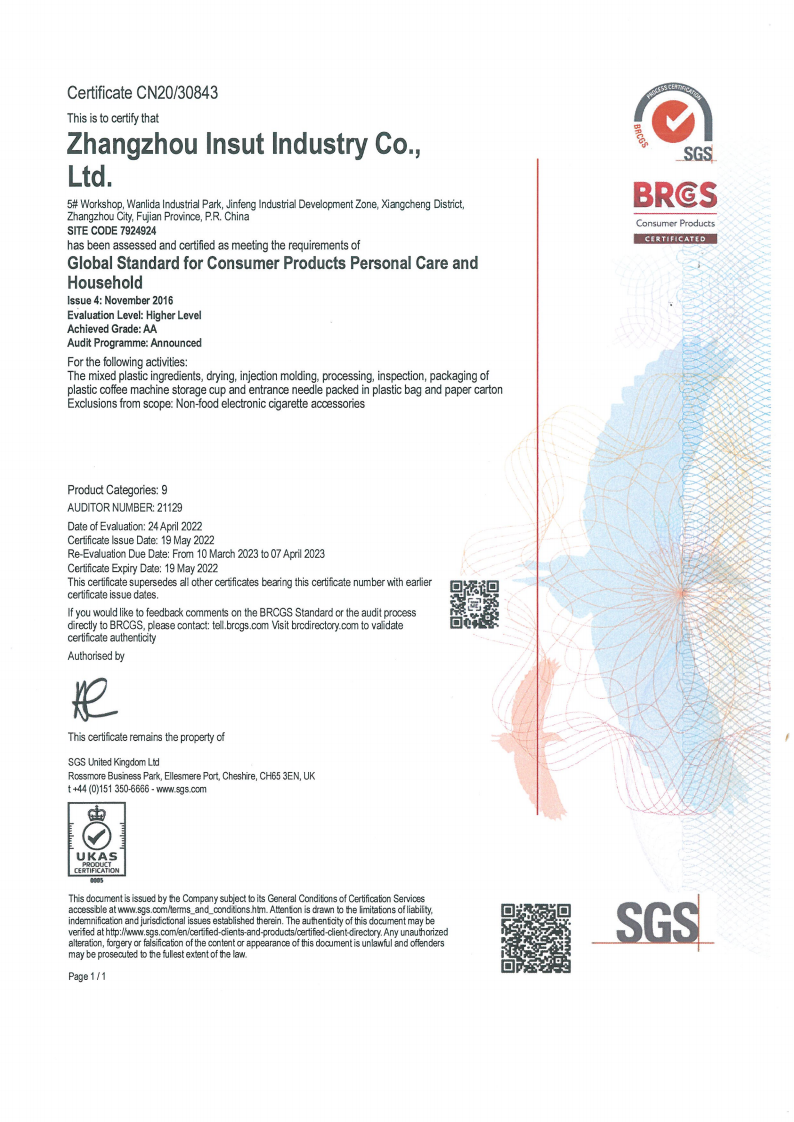

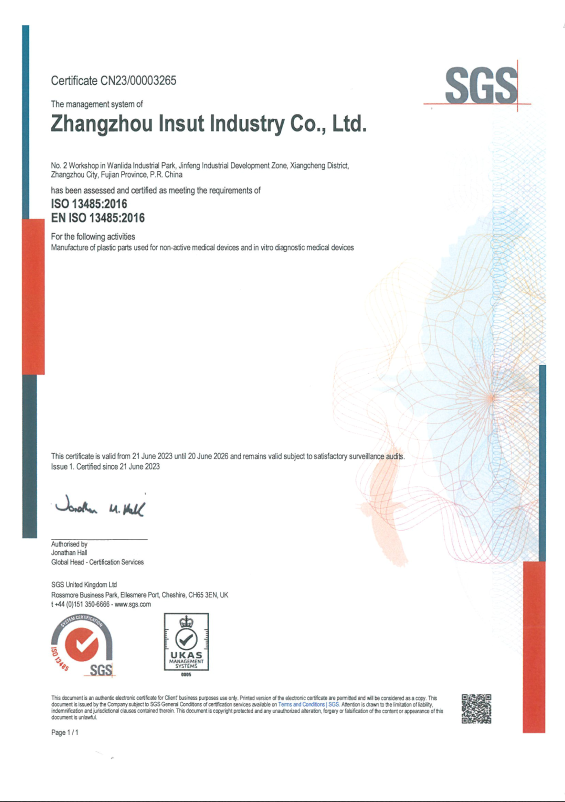

Zhangzhou Insut Industry Co., Ltd. was established in 2015, which is a wholly-owned subsidiary invested by Xiamen Intretech (Stock Code: 002925) , focus on precision plastic mold design and manufacturing, precision plastic structural parts injection molding, surface treatment and assembly, has formed research and development, design, production and sales of integrated service system. Insut has passed BRC, ISO9001, IATF16949, ISO13485, ISO14001 and other system certification. Currently the total area of company is 100,000 square meters, with more than 1200 of staff. At the same time, as a wholly-owned subsidiary of Intretech, sharing the group’s resources platform, it has formed a highly informative and automated intelligent manufacturing system to meet the collaborative development, customized services, flexible production, information interconnection and other integrated service needs. Insut upholds the core concept of“Team, Promptness, Prosperity, Sibling”, with world-class equipment, makes the first-class products, committed to become a global leader in precision structural intelligence manufacturer! |

History

History

Zhangzhou Insut passed the integration of industrialization and industrialization and IATF16949 certification.

Zhangzhou Insut passed the integration of industrialization and industrialization and IATF16949 certification.

Fujian Insut was incorporated.

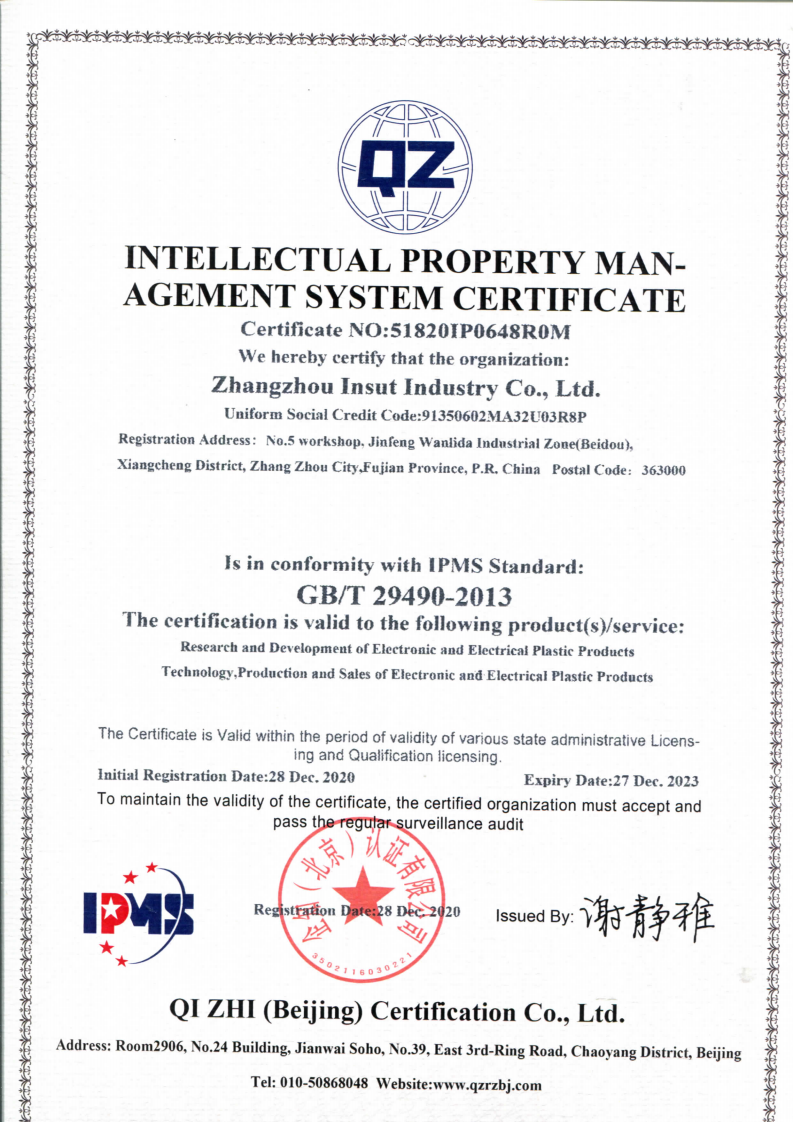

Zhangzhou Insut won the provincial leading enterprise of industry and information technology in Fujian Province, and passed ISO13485, BRC, intellectual property certification.

Insut (Malaysia) GP factory was established.

Insut (Hungary) was established and started production.

Zhangzhou Insut was selected as the third batch of green factories in Fujian Province.

Zhangzhou Insut high-end intelligent manufacturing base laid the foundation.

Insut (Malaysia) passed ISO 14001, ISO/IATF16949 certification

Zhangzhou Insut water-based paint spraying center plant was completed and accepted.

Zhangzhou Insut high-end intelligent manufacturing base put into operation.

The Mould Department of Zhangzhou Insut High-end Intelligent Manufacturing Base was established.

Quality authentication

Quality authentication

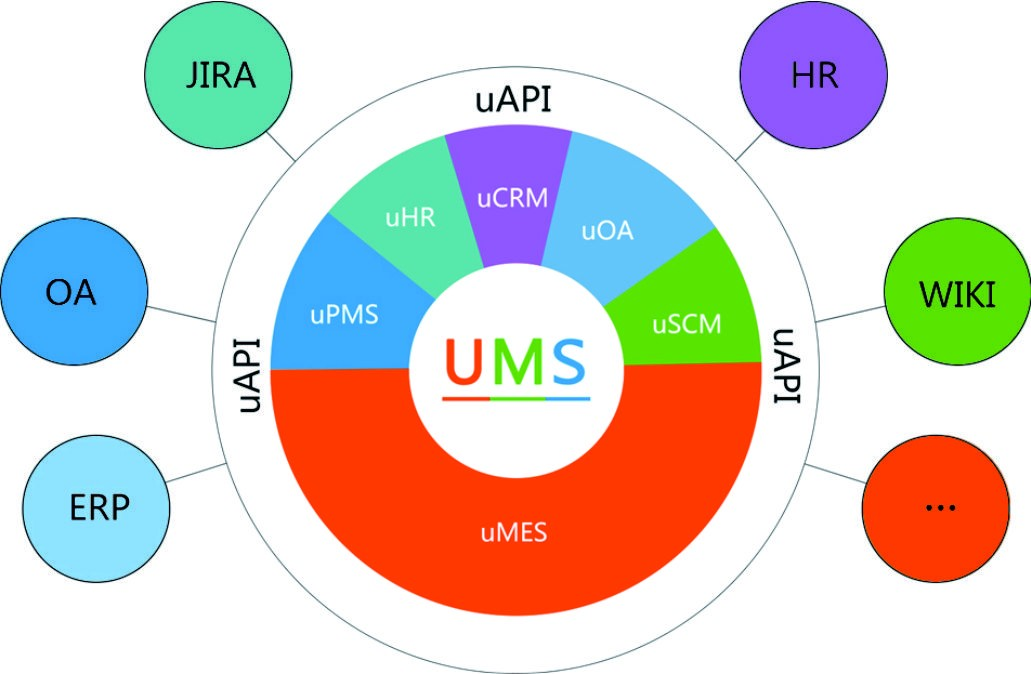

UMS System

UMS System

UMS United Management System:

Based on big data and Intretech Cloud, UMS efficiently integrates information management software, such as ERP (Enterprise Resource Planning), OA (Office Automation), PLM (Product Lifecycle Management), CRM (Customer Relationship Management), HR (Human Resource), WiKi (Corporate Knowledge Base) and fixed-assets management, etc. UMS focuses on providing automation and informatization solution for traditional manufacturing industry and strategic emerging industry to meet different demandson management software among different-scale enterprises,help enterprises to change the production management moderadically, improve quality and efficiency and create higher value.

Applications:Electronics, Food & Beverage, Petro-chemistry, Mechanical, Iron and steel, Automobile, Communications equipment, Semiconductor industry, Medical industry and Furniture industry, etc.

Manufacturing Execution Module 【Module Overview】 Manufacturing execution module is a customized digital information integration system combining production operation process and actual requirements of different enterprise, which aims at lean Manufacturing. The module is used for product life cycle management in manufacturing industry, including plans, material purchasing, work order, quality track, data collection, product packaging and inventory management, etc. |

Production Plan Management: Manage all process of MTO manufacturing through acquiring production plan instruction in UMS. According to planning instruction of each order, UMS will automatically manage the production schedulingthrough combining all resources in workshop, such asoperators, machinery,materials, operation process, production capacity, etc. In actual production, it can adjust the production plan based on productionstatus to ensure smooth production of each order.

Just-in-time Production Control: UMS system can acquire real-time production status of each process automatically. Managers can grasp the status of each order, each product, each component, each operator, each machine, each process and each production line to deploy production tasks according to actual production demand.

Production Quality Control: UMS system can collect real-time data of production models, station, project quality inspection, etc., and can automatically record the problems in production.Then

Production Process Track: Each product will be bonded with a serial number and form complete production data files in production process. Our customer can select meticulous and precise production information through serial number, such asoperators, machines, time,manufacturingparametersthat each process refer to.

Real-timeProduction Warning: Timely monitor the executive conditionof index in production process according to parameter index defined for each process. When actual production deviates from the set target and produces abnormity, UMS will give real-time feedback to managers.

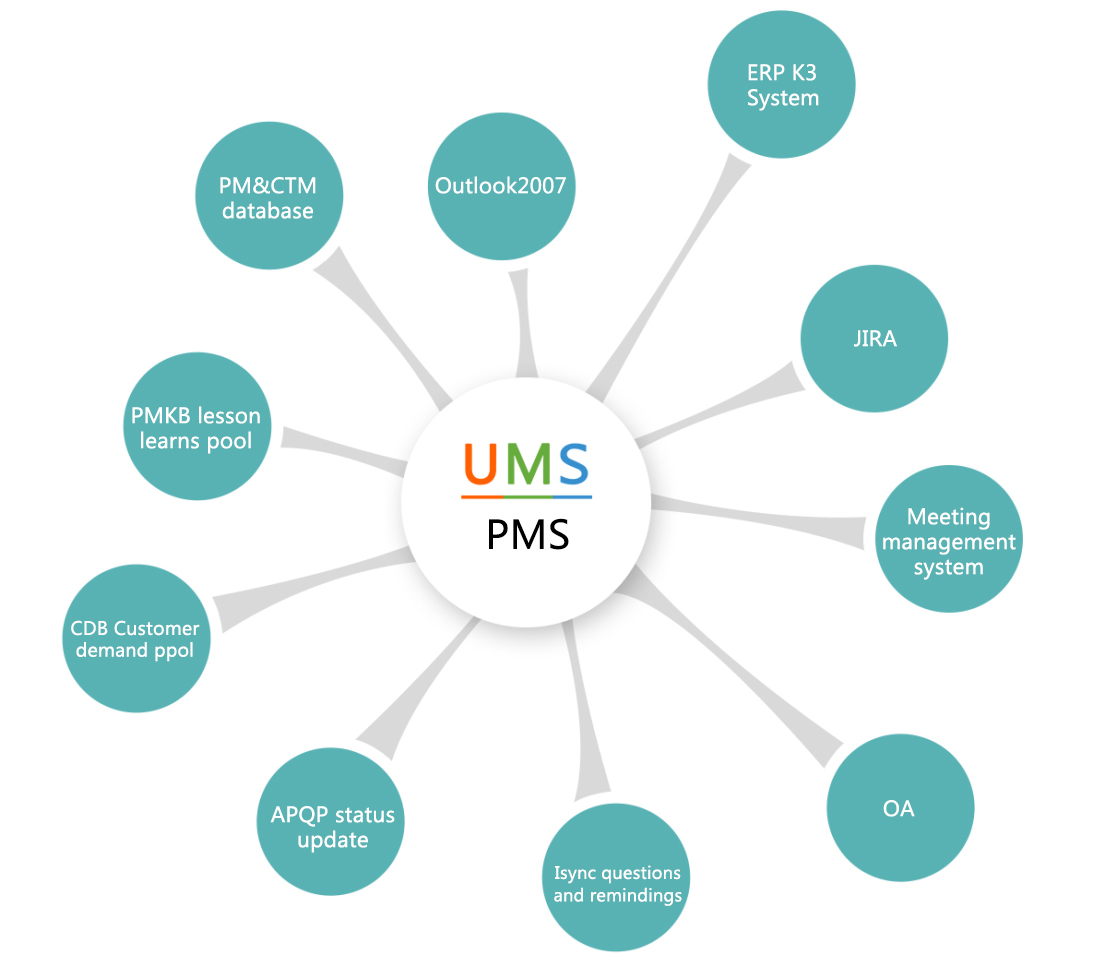

OA Module 【Module Overview】 | Project Management Information Module 【Module Overview】 Based on our company architecture, ISync system includes various elements that Project Management refers to, meets projectsintegral management under complicated condition,which automaticallypresentprojects statesthrough sub-item and concentration to provide an integrated information platform.Conclude and concentrate projects information of one or more project or the same customer, present projects’ variation and inquiry, answer or reminding of CDB,PMKB through managing APQP outputs. |

wxl@insut.com

wxl@insut.com Wanlida Industrial Park, Jinfeng Development Zone, Zhangzhou City, Fujian Province

Wanlida Industrial Park, Jinfeng Development Zone, Zhangzhou City, Fujian Province